Pivotal Role of Ammonia and Catalyst Technologies in the Global Hydrogen Economy

2025.12.05

🔍 Ammonia offers value far beyond simply carrying a high density of hydrogen. With its higher boiling point and larger molecular weight compared to hydrogen, ammonia is far more stable and cost-efficient to store and transport. These physical advantages play a crucial role in shaping the economic viability of the entire supply chain.

This article explores the technical characteristics of the ammonia-based hydrogen supply chain along with the latest global trends.

The energy industry is undergoing a fundamental transformation. As climate change and environmental pollution accelerate, the hydrogen economy has emerged as an alternative to fossil-fuel-based energy systems. With countries expanding hydrogen adoption, the question of how to store and transport hydrogen has become a major challenge—placing ammonia at the center of the discussion as a game-changing solution.

Why Is Ammonia Suitable as a Hydrogen Carrier?

1) High Hydrogen Density and Efficient International Transport

According to physical property data from the U.S. Department of Energy (DOE), ammonia can store about 1.5 times more hydrogen per unit volume than liquid hydrogen. Liquid ammonia stores approximately 108 kg of hydrogen per cubic meter, whereas liquid hydrogen stores about 71 kg under the same volume (1 m³). This difference is critical for international shipping and large-scale storage. Transporting more energy with the same equipment leads to significantly improved economics and operational efficiency.

2) No Need for Extreme Cryogenic Conditions

Ammonia remains liquid at –33°C, requiring much less energy for cooling and storage. In comparison, liquid hydrogen boils at –253°C, demanding highly advanced cooling systems, continuous energy input, and operations that inevitably cause boil-off losses.

Because ammonia imposes far fewer technical and energy burdens, it can be stored and transported safely with simpler equipment—minimizing losses and reducing operating costs, particularly over long distances.

3) Rapid Scalability Using Existing Global Infrastructure

Ammonia has been produced, transported, and stored at scale for decades in the fertilizer industry. As a result, the global infrastructure—safety regulations, transport vessels, storage tanks, and port facilities—is already well-established. The International Renewable Energy Agency (IRENA) reports that more than 120 ports worldwide are equipped to handle ammonia, allowing rapid expansion of renewable-hydrogen-based ammonia trade with minimal new construction.

Leveraging existing infrastructure dramatically accelerates commercialization and is a key reason ammonia is emerging as the backbone of international hydrogen trade.

Global Trends and Outlook

The International Energy Agency’s Global Hydrogen Review 2024 notes that about 85% of announced international hydrogen trade projects plan to transport hydrogen in ammonia form. Although many low-carbon hydrogen projects are still in early stages, projects that reached final investment decision (FID) doubled—from 1.7 million tons in 2023 to 3.4 million tons in 2024—showing rapid growth in ammonia-based production and export projects.

A joint 2024 report by IRENA and the World Trade Organization (WTO) projects that the global ammonia market could reach 688 million tons by 2050, more than twice its current size. The additional demand will come largely from:

- Renewable ammonia for fertilizers: Most fertilizer ammonia today is fossil-based, requiring a transition to renewable hydrogen.

- Marine fuel: With stricter IMO decarbonization rules, ammonia is emerging as the most realistic alternative for large vessels.

- Hydrogen carrier: Transporting renewable hydrogen as ammonia is becoming the standard in international trade.

The maritime sector is one of the fastest-growing markets for ammonia. According to Det Norske Veritas (DNV), 39 ammonia-fueled vessels have already been ordered as of 2025, with the first deliveries scheduled between 2025 and 2026. Germany’s MAN Energy Solutions has also received orders for about 30 ammonia dual-fuel, two-stroke engines, advancing large-scale testing and accelerating commercialization.

Ammonia Cracking: The Key to Efficient Long-Distance Hydrogen Supply

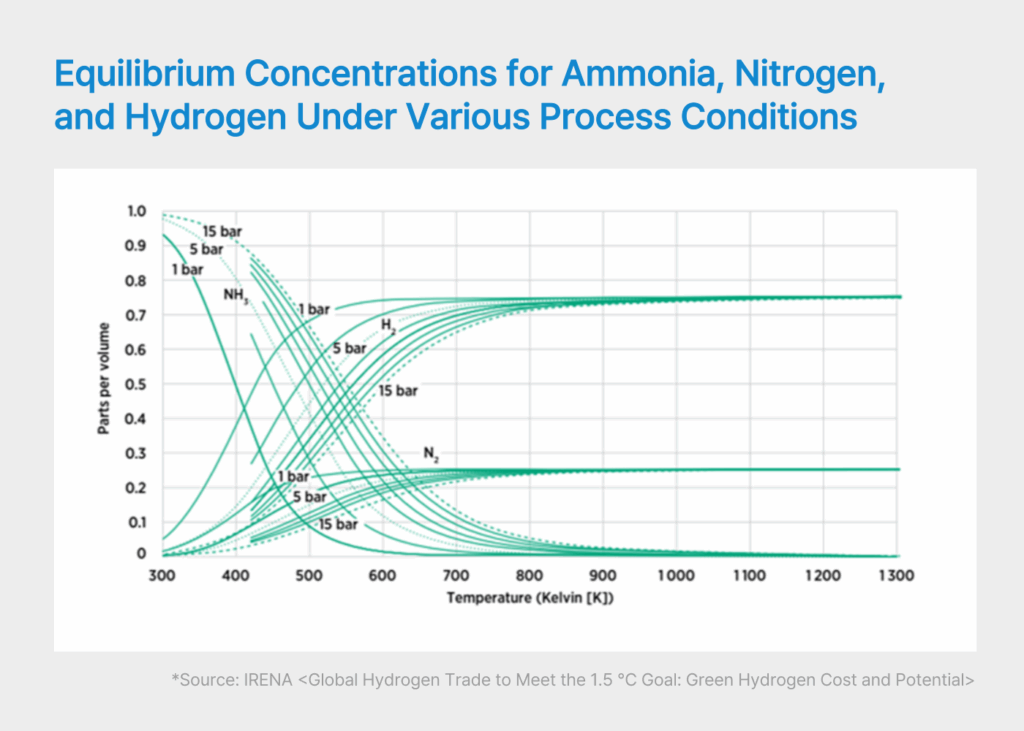

In an ammonia-based hydrogen supply chain, the critical step is cracking, which decomposes ammonia into nitrogen and hydrogen (NH₃ → N₂ + 3H₂). This reaction typically requires 500–550°C, and the conversion process incurs 15–33% energy losses, making high-activity, low-temperature catalysts a core focus of global R&D.

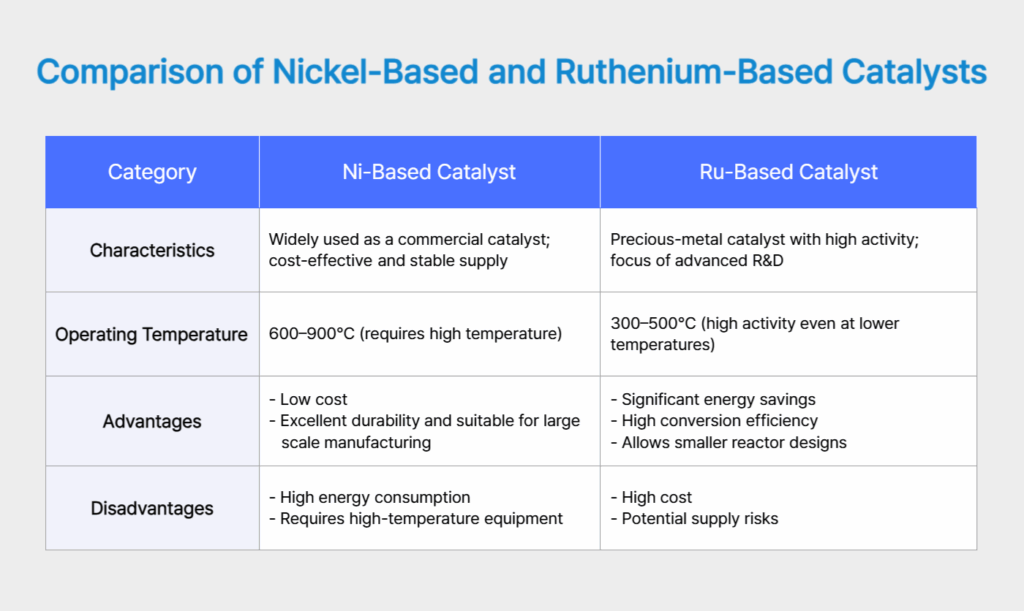

Ni-based catalysts, widely used in industry, offer advantages in cost and durability but require relatively high temperatures, increasing energy consumption. Ru-based catalysts, on the other hand, achieve high conversion rates even at 300–500°C, making them a leading technology in global research. Lower reaction temperatures reduce both equipment size and energy cost—key factors for improving supply chain efficiency.

✅ Key Technology for Eco-Friendly Hydrogen Transportation: Ammonia Cracking Catalyst

Heesung Catalysts’ R&D Capabilities and Achievements

The efficiency of long-distance hydrogen supply depends heavily on the catalyst used in the cracking process. Low-temperature, high-efficiency, and high-durability catalysts are considered essential for future supply chain development, and Ru-based low-temperature catalysts have become a central area of global research.

Heesung Catalysts has continued R&D focused on low-temperature and high-durability catalysts. Leveraging expertise in Ru- and Ni-based catalysts—including nanostructure control, impregnation technologies, and evaluation platforms spanning laboratory to pilot scale—the company is advancing its technological capabilities.

Recently, Heesung Catalysts presented its vision for Net-Zero marine fuel catalysts and high-efficiency ammonia cracking catalysts at the Korean Society of Clean Technology’s 30th-anniversary conference, highlighting decarbonization strategies for the shipbuilding and marine industries. We also received an Outstanding Paper Award from the Korean Hydrogen and New Energy Society for our research on hydrogen production via ammonia decomposition over Ru-based catalysts, demonstrating our recognized technological strength. Heesung Catalysts will continue developing catalyst solutions that contribute meaningfully to carbon neutrality and the growth of the hydrogen economy.

➡️ Related Reads

🔗 Key to the Clean Hydrogen Era: Ammonia Cracking Catalyst Technology