Catalyst Q&A Series – Part 2: The Role of Catalysts in a Carbon-Neutral, Hydrogen-Powered Future

2025.07.02

🔎 As the world moves toward carbon neutrality and a hydrogen-based economy, industries are turning to technological innovation to overcome growing challenges.

Reducing greenhouse gas emissions, improving energy efficiency, and optimizing processes are no longer distant goals. They have become immediate priorities. Catalysts, once considered just one part of industrial operations, are now recognized as key technologies that drive the energy transition and support carbon reduction efforts.

In this second episode, we examine the role of catalysts in enabling a carbon-neutral, hydrogen-powered future.

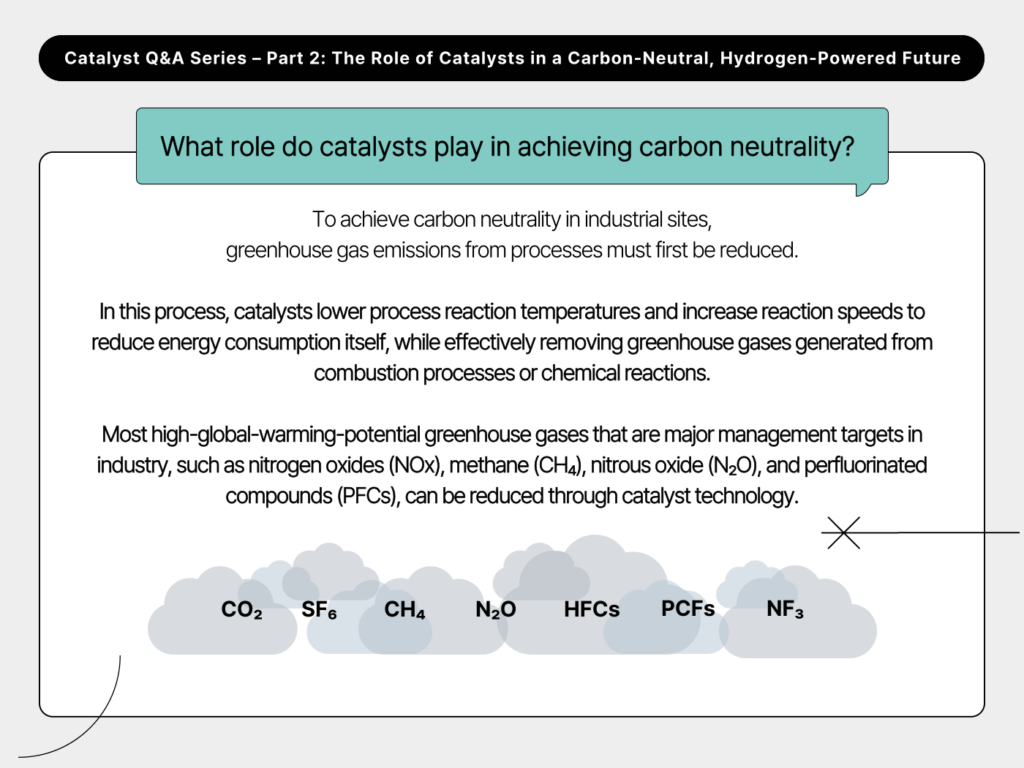

1. What role do catalysts play in achieving carbon neutrality?

To achieve carbon neutrality in industrial sites, greenhouse gas emissions from processes must first be reduced. In this process, catalysts lower process reaction temperatures and increase reaction speeds to reduce energy consumption itself, while effectively removing greenhouse gases generated from combustion processes or chemical reactions. Most high-global-warming-potential greenhouse gases that are major management targets in industry, such as nitrogen oxides (NOx), methane (CH₄), nitrous oxide (N₂O), and perfluorinated compounds (PFCs), can be reduced through catalyst technology.

✅ Harmony Between the Environment and Industry: Heesung Catalysts Leads the Way

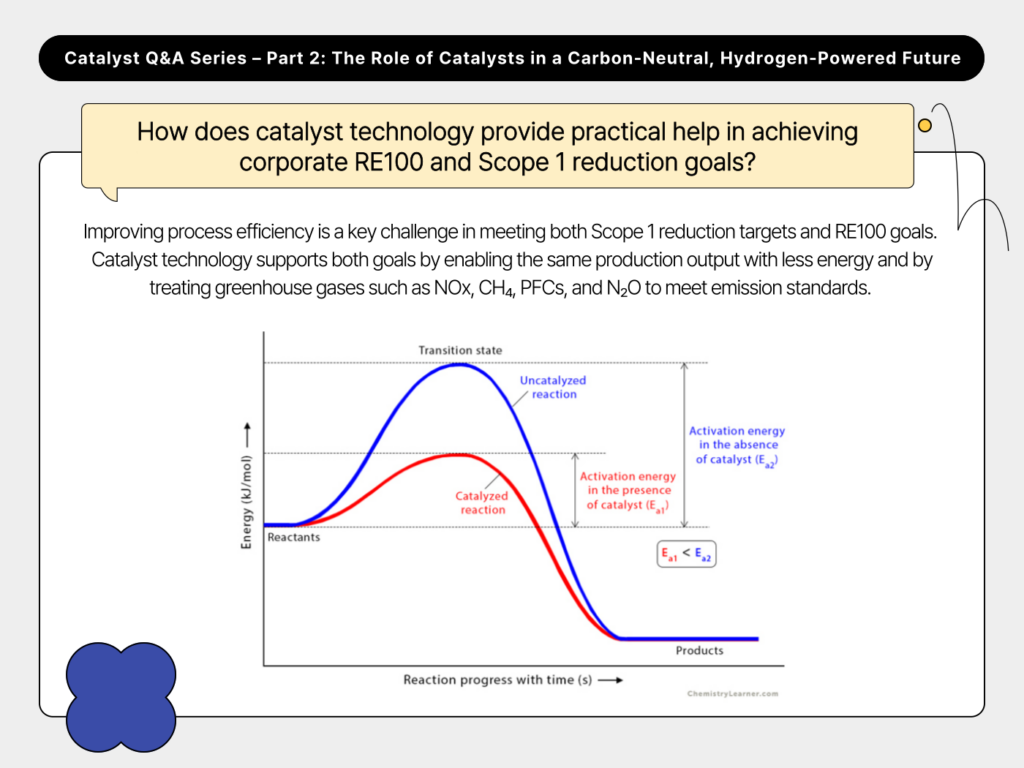

2. How does catalyst technology provide practical help in achieving corporate RE100 and Scope 1 reduction goals?

Improving process efficiency is a key challenge in meeting both Scope 1 reduction targets and RE100 goals. For RE100, reducing energy consumption contributes indirectly by lowering the demand for non-renewable energy. In contrast, Scope 1 requires a direct reduction in greenhouse gas emissions from production processes.

Catalyst technology supports both goals by enabling the same production output with less energy and by treating greenhouse gases such as NOx, CH₄, PFCs, and N₂O to meet emission standards. This leads to measurable improvements in indicators related to greenhouse gas reporting, ESG evaluations, and green finance certifications.

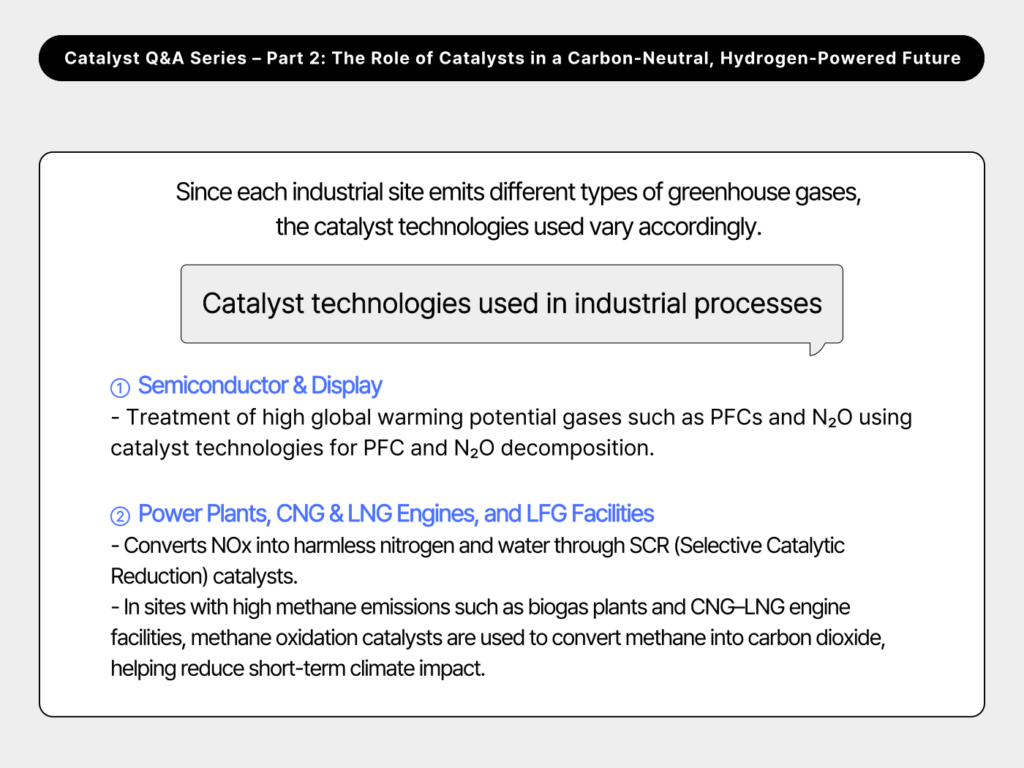

3. What catalyst technologies are used to reduce greenhouse gas emissions in industrial processes?

Since each industrial site emits different types of greenhouse gases, the catalyst technologies used vary accordingly. Power plants and steel mills commonly use SCR (Selective Catalytic Reduction) catalysts to convert nitrogen oxides into harmless nitrogen and water. Semiconductor and display manufacturing processes use PFCs and nitrous oxide decomposition catalysts to treat high–global warming potential gases such as PFCs and nitrous oxide.

Methane oxidation catalysts are applied in facilities with high methane emissions, such as biogas plants and CNG or LNG engines. These catalysts convert methane into carbon dioxide, helping reduce its short-term impact on the climate. Applying tailored catalyst solutions that reflect the characteristics of each industry is a fundamental strategy in today’s greenhouse gas management.

✅ Greenhouse Gas Reduction Catalysts

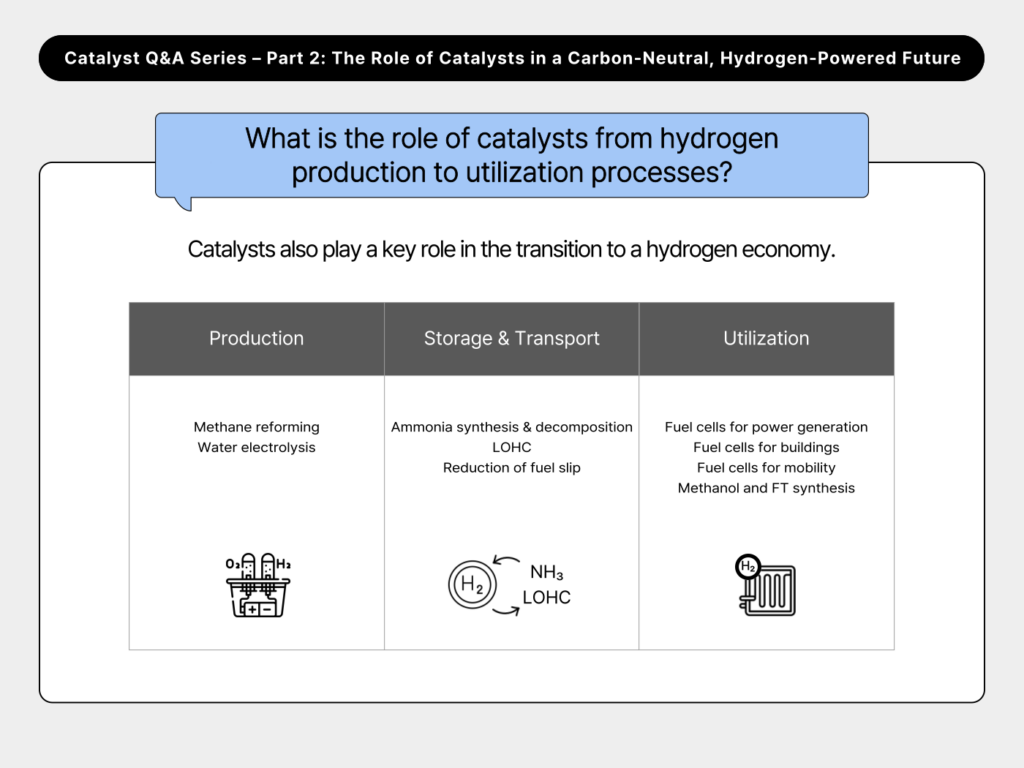

4. What is the role of catalysts from hydrogen production to utilization processes?

In the production phase, especially in water electrolysis, electrode catalysts determine the speed and efficiency of hydrogen generation. Heesung Catalysts is developing commercial PEM electrolysis catalysts and also advancing AEM catalyst technology, which is gaining attention as a promising next-generation option.

In the transportation and storage phase, ammonia is attracting interest as a hydrogen carrier due to its high energy density and compatibility with existing infrastructure. However, to use ammonia as hydrogen, a decomposition process is required, and this process depends on catalysts to improve hydrogen yield and reduce reaction temperatures.

Catalysts remain critical in the final utilization phase. In fuel cells, they facilitate the electrochemical reaction between hydrogen and oxygen at the electrode, increasing reaction activity and improving power output. Heesung Catalysts continues to enhance the durability and performance of platinum-based catalysts used in this stage.

✅ Next-Generation Clean Energy: Hydrogen Production Catalyst

✅ Key Technology for Eco-Friendly Hydrogen Transportation: Ammonia Cracking Catalyst

5. What catalyst solutions does Heesung Catalysts provide for carbon neutrality response?

Heesung Catalysts offers a broad portfolio of solutions that support carbon neutrality across various industrial sectors. Our offerings include electrode catalysts for hydrogen production and fuel cells, ammonia cracking catalysts, as well as catalysts for SCR, N₂O decomposition, methane oxidation, and PFC reduction.

We provide customized solutions tailored to the specific process characteristics of each industry, offering end-to-end support from technical consulting to product supply and performance optimization. Heesung Catalysts is actively developing next-generation catalyst technologies for hydrogen production and utilization, and we are committed to accelerating innovation to support the global transition to clean energy and the realization of carbon neutrality.

✅ Fighting climate change with decarbonising catalysts that drive change to a sustainable future

➡️ Read More