Carbon Neutral Era: Examining the Current State of Catalyst Technology – Part 2

2025.05.12

The Korean Institute of Chemical Engineers Heesung Catalysts Symposium Review (Part 2)

In Part 1, we examined climate and environmental catalyst technologies for greenhouse gas reduction and automotive catalyst technology development trends for future emission regulation response from the symposium presentations. In this Part 2, we introduce catalyst technologies supporting hydrogen production and utilization, and the development status of electrode catalysts for fuel cells and water electrolysis.

Hydrogen Emerges as the Center of Decarbonization

To respond to the climate crisis and achieve carbon neutrality, the world is transitioning from fossil fuel-centered industrial structures. At the center of this change is ‘hydrogen’. Hydrogen, which can store electricity and be utilized as fuel in various industries, is not simply an energy substitute but a key driving force accelerating decarbonization across industry, power generation, and mobility sectors.

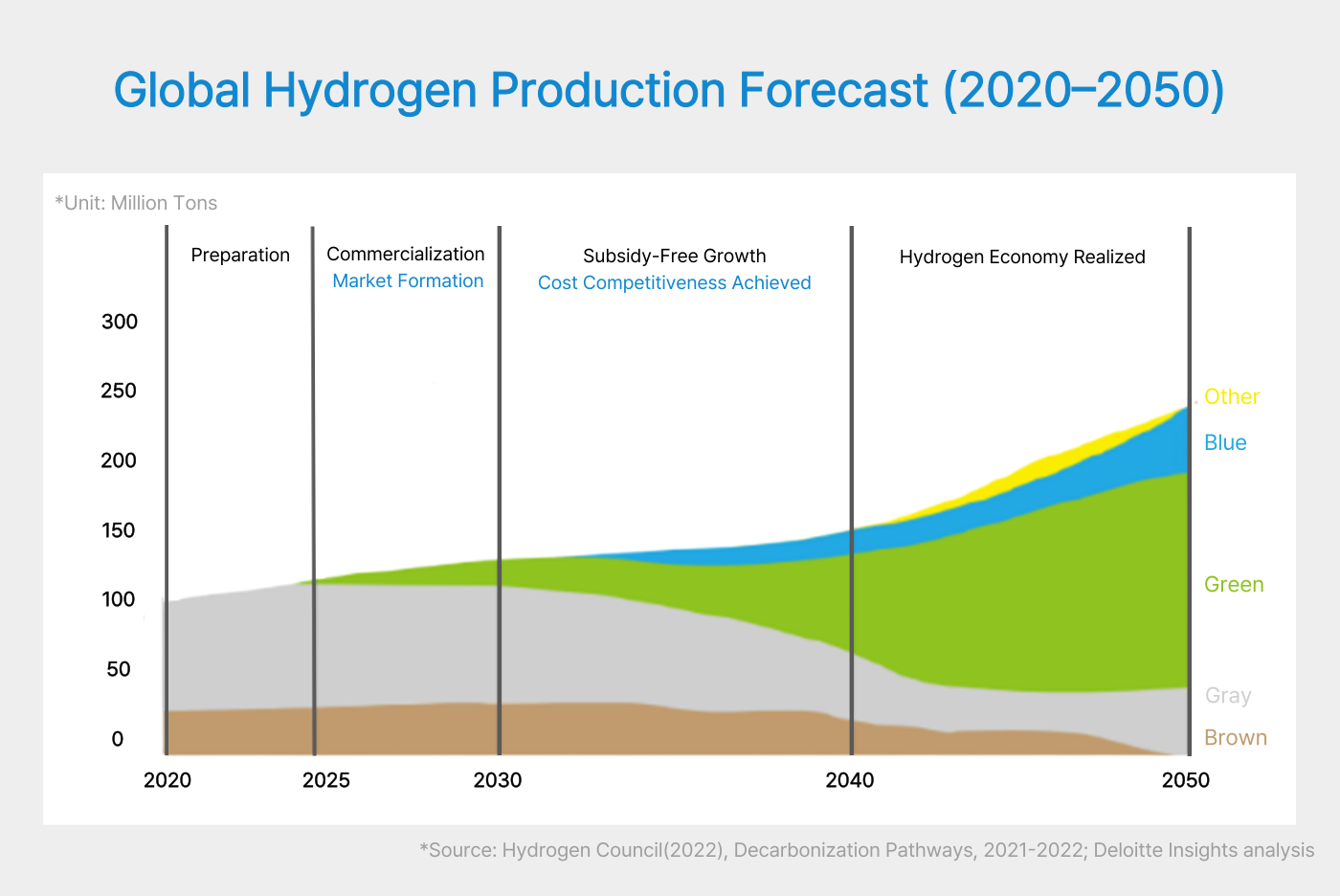

According to Deloitte’s “Climate Technology and the Future of the Hydrogen Economy” report, global hydrogen production in 2050 is expected to reach 259 million tons annually, approximately five times the current level, with over 78% projected to be converted to clean hydrogen such as green hydrogen* and blue hydrogen*.

Currently, we are in the stage of laying the foundation for the hydrogen economy and forming initial markets. After expanding clean hydrogen production, strengthening national strategies, and securing economic feasibility, a hydrogen-centered energy system is expected to begin in earnest after 2040.

*Green hydrogen: Hydrogen produced through water electrolysis using renewable energy

*Blue hydrogen: Hydrogen produced by capturing and storing CO₂ generated during fossil fuel-based production processes to reduce carbon emissions

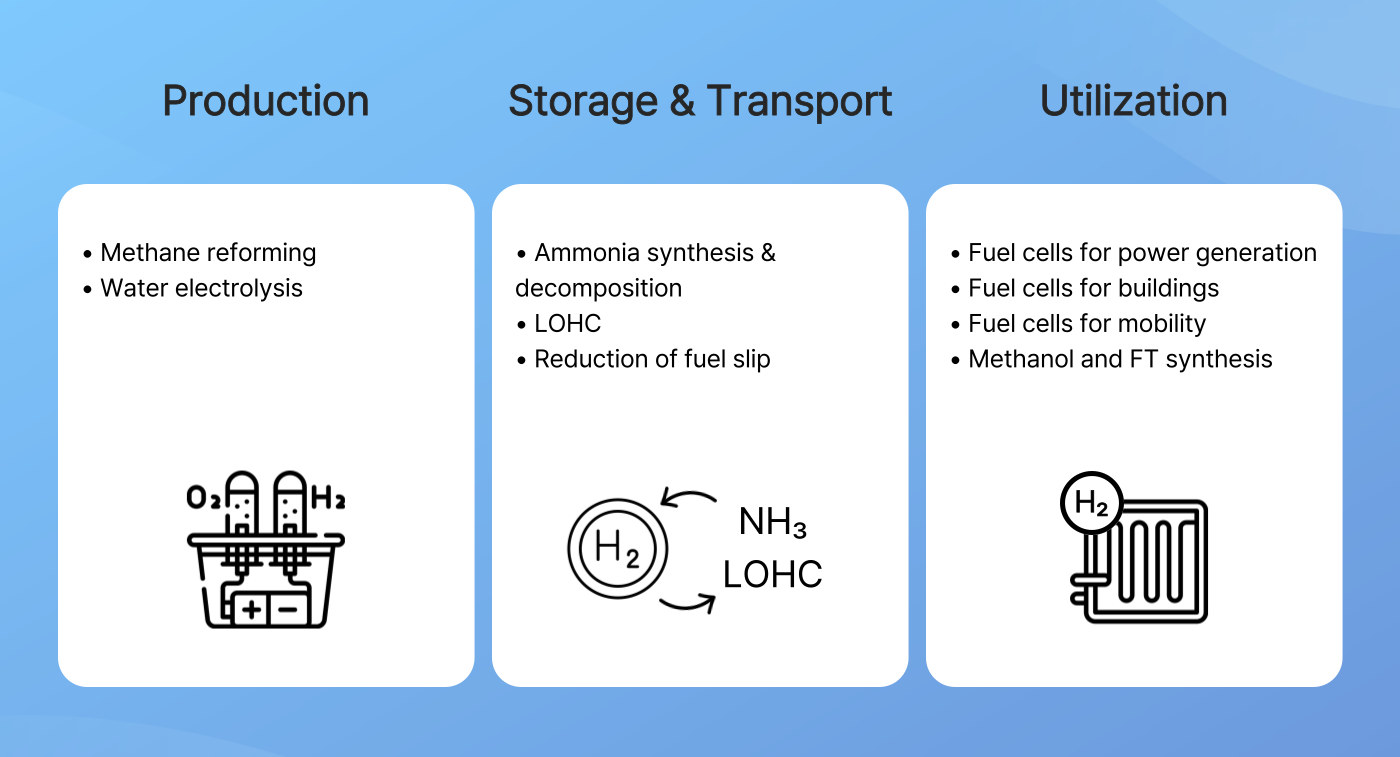

To establish a hydrogen-centered energy system, the key is securing technical efficiency and economic feasibility throughout the entire process from hydrogen production to storage, transportation, and utilization. The core role in this process is played by ‘catalysts’. In various processes and systems needed to realize the hydrogen economy, catalysts serve as important foundational technologies that increase reaction efficiency, reduce energy consumption, and control pollutants.

Catalyst Technology That Has Driven Industry

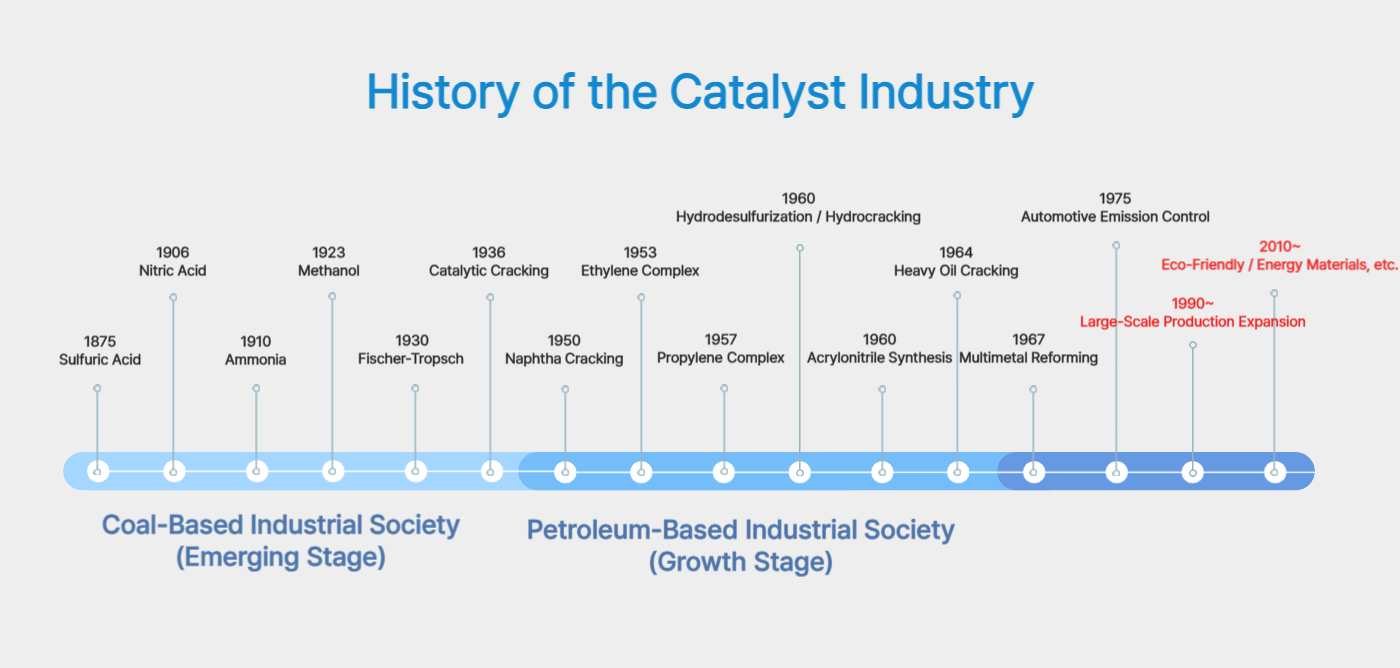

Catalyst technology has played a major role in modern industrial development. Starting with sulfuric acid production in 1875, it became an essential technology throughout the chemical industry and quickly spread as a core process technology in the coal-based industrial society. In the 1970s, environmental regulation response began in earnest with the development of Three-Way Catalysts (TWC) for automotive emission reduction, and since the 1990s, large-scale catalyst production systems have been established centered on advanced countries such as the United States, Europe, and Japan. Since the 2010s, development of eco-friendly energy materials and greenhouse gas reduction catalyst technologies has been accelerating to respond to the era’s challenges of carbon neutrality realization and energy transition.

Today, catalyst technology goes beyond simply promoting chemical reactions. It has emerged as a core solution that increases energy efficiency, reduces greenhouse gases, and leads clean fuel production. Efficiency improvement of renewable energy systems such as solar and wind power, technology converting biomass into fuel and chemical raw materials, and demand for high-performance catalysts following the spread of electric and hydrogen vehicles continue to increase. Other major growth areas include clean fuel production using synthesis gas, technology supporting the entire hydrogen industry cycle, and advancement of CCUS (Carbon Capture, Utilization and Storage) processes. As a core technology leading energy transition and carbon neutrality, the role of catalysts is growing ever larger.

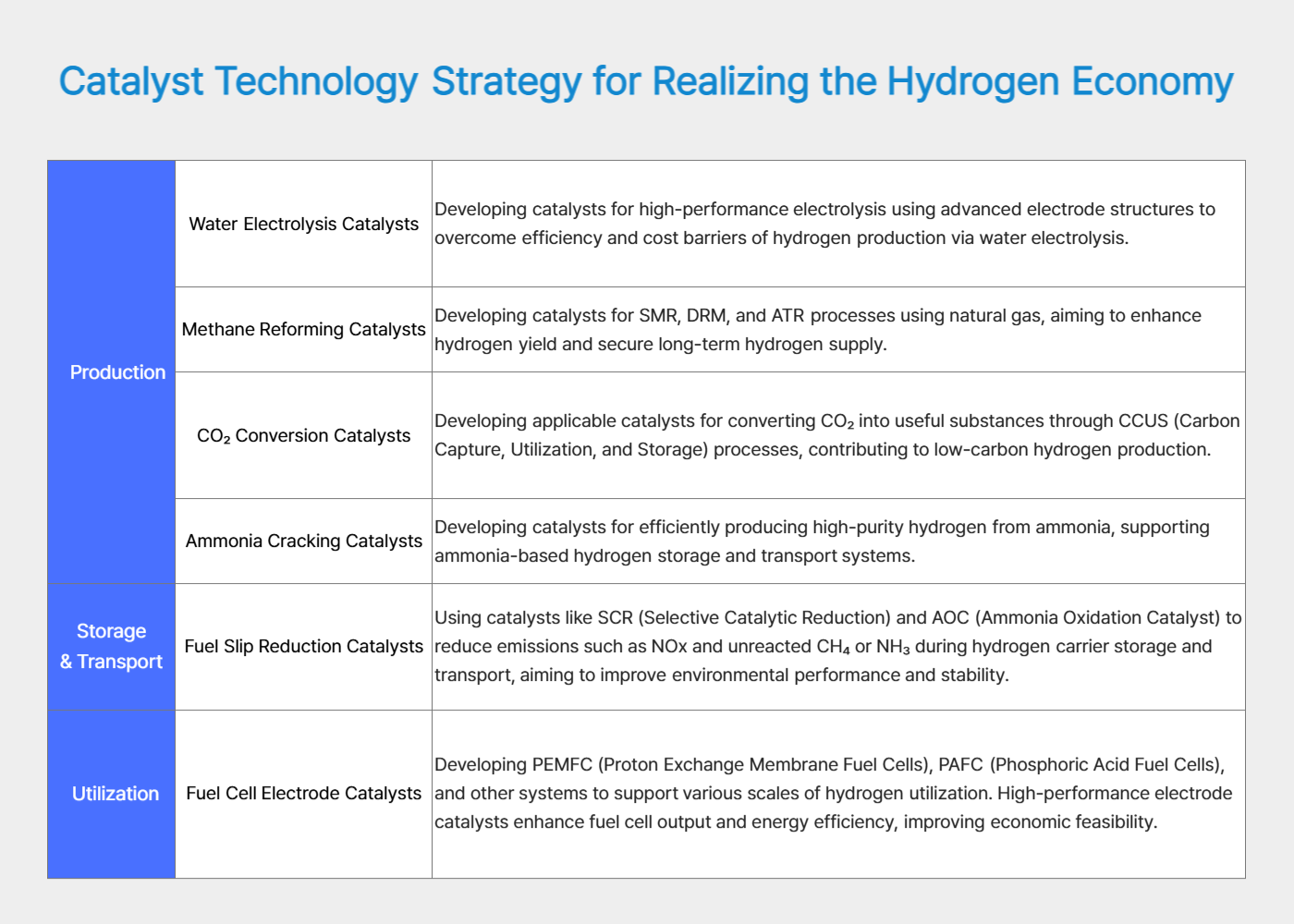

Total Catalyst Solutions for Hydrogen Economy Realization

Heesung Catalysts aims to create a more efficient and sustainable hydrogen ecosystem through catalyst technologies that encompass the entire value chain of the hydrogen industry for hydrogen economy expansion and carbon neutrality realization.

To this end, we have secured catalyst technologies optimized for various hydrogen production processes including water electrolysis, reforming, CO₂ conversion, and ammonia decomposition. In the storage and transportation stages, minimizing fuel loss and pollutant emissions is key, and we also have catalyst solutions that can control untreated fuel and secondary pollutants that may occur during this process.

Additionally, in fuel cell systems that convert hydrogen to electrical energy, the reaction efficiency and durability of electrode catalysts determine core performance. Heesung Catalysts is applying high-performance catalysts suitable for various fuel cell types to enhance both reliability and economic feasibility of hydrogen utilization technologies.

Based on this technology vision, Heesung Catalysts introduced research achievements and development directions of hydrogen-based catalyst technologies at the Korean Institute of Chemical Engineers Heesung Catalysts Special Symposium. Focusing on the main content covered in the presentations, we will examine the technology development status from hydrogen production to storage·utilization, and electrode catalyst development.

Catalyst Technologies for Hydrogen Production and Utilization Toward a Hydrogen Society

Heesung Catalysts is developing solutions applicable throughout the hydrogen industry, including hydrogen production processes, storage systems, and utilization products, based on chemical catalyst technology.

1. Hydrogen Production Stage

1) Desulfurization Catalyst

The first step in the hydrogen production process is removing sulfur contained in fuel gas. If sulfur remains, it rapidly poisons catalysts in subsequent reforming or Water-Gas Shift (WGS) reactions, significantly affecting process efficiency and economic feasibility.

Heesung Catalysts is developing two types of desulfurization solutions. At low temperatures, we remove sulfur compounds such as THT (Tetrahydrothiophene) and TBM (Tertiary Butyl Mercaptan) through adsorption technology using Cu/Zeolite and Cu-Mn composite catalysts. At high temperatures, we effectively remove sulfur components through HDS (Hydrodesulfurization) reactions and ZnO-based adsorption catalysts. Through this, we are dramatically extending the catalyst life of the entire hydrogen production process.

2) Methane Reforming Catalyst

Methane (CH₄) is the cheapest and most abundant hydrogen source, and Heesung Catalysts is developing catalysts that can respond to various reforming processes converting methane to hydrogen.

- Steam Methane Reforming (SMR): CH₄ + H₂O → CO + 3H₂

- Dry Reforming of Methane (DRM): CH₄ + CO₂ → 2CO + 2H₂

- Catalytic Partial Oxidation (CPOX): CH₄ + ½O₂ → CO + 2H₂

- Auto Thermal Reforming (ATR): A method combining SMR and CPOX to optimize process heat balance

Heesung Catalysts is developing Ni, Ru, and Ni-M alloy catalysts suitable for each process’s required conditions, and is pursuing support design and sulfur resistance enhancement together to maintain stability even in high-temperature, long-term operating environments.

3) Water Gas Shift Catalyst

This is a process that converts CO remaining in synthesis gas generated after methane reforming to hydrogen.

- CO + H₂O → CO₂ + H₂

Heesung Catalysts is developing both high-temperature (Fe₂O₃-based) and low-temperature (Cu-ZnO-Al₂O₃-based) catalysts, applying them to the front and back ends of the process respectively to maximize overall hydrogen yield.

2. Hydrogen Storage·Transportation Stage

1) Ammonia Cracking Catalyst

Ammonia (NH₃) is attracting attention as a substance that contains no carbon and has excellent hydrogen storage capability. However, it involves technical challenges such as high-temperature reactions, NOx generation control, and toxicity. Heesung Catalysts is developing catalyst technology that can increase ammonia decomposition efficiency and suppress NOx generation, preparing for the commercialization of ammonia-based hydrogen storage·transportation solutions.

✅ Key Technology for Eco-Friendly Hydrogen Transportation: Ammonia Cracking Catalyst

2) Liquid Organic Hydrogen Carrier (LOHC) Storage Catalyst

LOHC is a technology that can transport hydrogen by storing it in organic compounds at room temperature and pressure. Heesung Catalysts is developing special catalysts that increase the efficiency of hydrogen dehydrogenation reactions, thereby strengthening the economic feasibility and reliability of LOHC systems.

3. Hydrogen Utilization Stage

1) Methanol Synthesis Catalyst

We are developing Cu-based catalysts applied to processes that synthesize methanol by reacting hydrogen with CO or CO₂.

- CO + 2H₂ → CH₃OH

- CO₂ + 3H₂ → CH₃OH + H₂O

Methanol is utilized for various purposes including hydrogen storage, fuel, and chemical product raw materials, and is evaluated as an important medium for realizing the hydrogen economy.

2) Fischer-Tropsch (FT) Synthesis Catalyst

We are also developing Fischer-Tropsch (FT) catalysts that produce liquid fuels such as diesel and gasoline using synthesis gas (Syngas). Co-based catalysts are optimized for high-purity CO environments, while Fe-based catalysts are optimized for environments containing CO₂, enabling response to various fuel production environments.

3) Sustainable Aviation Fuel (SAF) Production Catalyst

We are also developing Methanol-to-Jet and FT catalysts that produce aviation fuel (E-jet) using hydrogen and CO₂. As SAF technology to reduce carbon emissions in the aviation sector, it is attracting attention as a key component of carbon neutrality strategies.

✅ Decarbonizing the Aviation Industry: The Rise of Sustainable Aviation Fuel (SAF)

Development Status of Electrode Catalyst Technologies for Fuel Cells and Water Electrolysis

The Key to Hydrogen Energy Implementation: Electrode Catalyst Advancement Strategy

To connect hydrogen production and utilization to actual energy systems, the role of electrode catalysts that determine the performance of fuel cell and water electrolysis systems is very important. Heesung Catalysts is enhancing the performance of electrode catalysts for fuel cells and water electrolysis through particle and surface structure control and support optimization based on high-activity, high-durability precious metal catalyst design.

1. Electrode Catalysts for Fuel Cells

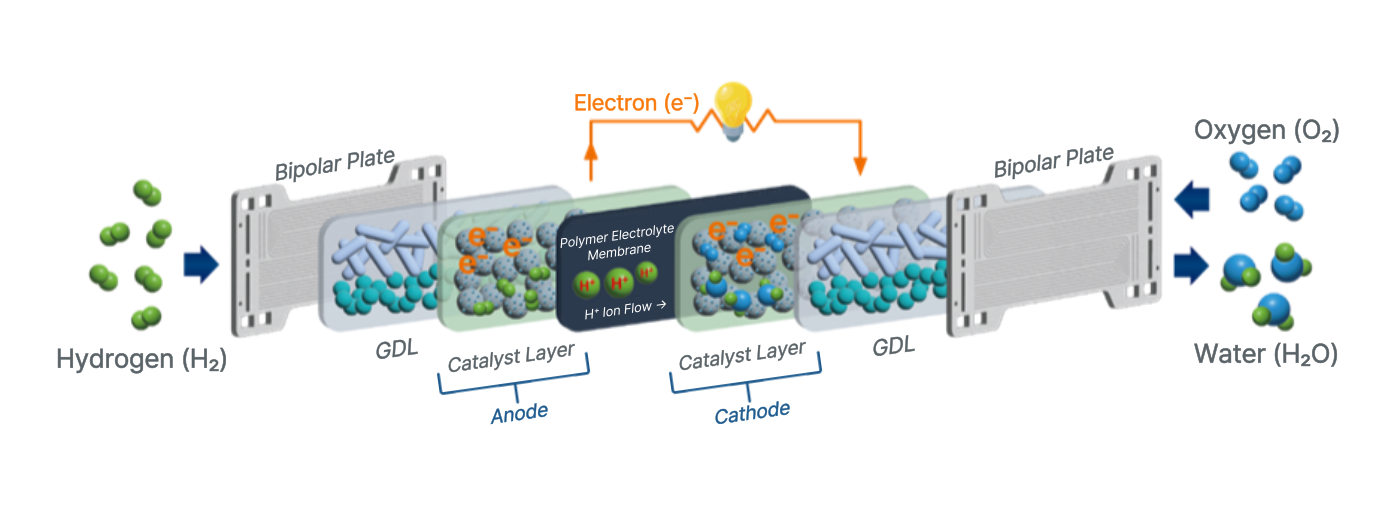

1) Proton Exchange Membrane Fuel Cell (PEMFC) Electrode Catalysts

PEMFC is the most widely used hydrogen fuel cell system, with high power density and fast startup characteristics. Heesung Catalysts responds to various Pt content conditions based on high-activity Pt-based catalysts, and has secured technology that reduces Pt usage while maintaining high activity through alloy catalyst design such as Pt-Co and Pt-Ni. Additionally, we are maximizing fuel cell stack performance by applying Pt-enriched skin structures to suppress transition metal dissolution and optimizing active site exposure and gas diffusion through mesoporous support design.

2) Phosphoric Acid Fuel Cell (PAFC) Electrode Catalysts

For PAFC systems that maintain stable output in high-temperature operating environments, heat resistance and catalytic layer structural stability are key. Heesung Catalysts is developing high-durability carbon support-based catalysts and Pt-X series core-shell alloy catalysts, applying precious metal composition optimization technology focused on suppressing catalyst particle dissolution and maintaining performance during oxidation-reduction cycles. Particularly, we are advancing high-durability design with the goal of achieving over 80,000 hours of long-term operation life through 3-layer Pt skin structures.

2. Electrode Catalysts for Water Electrolysis

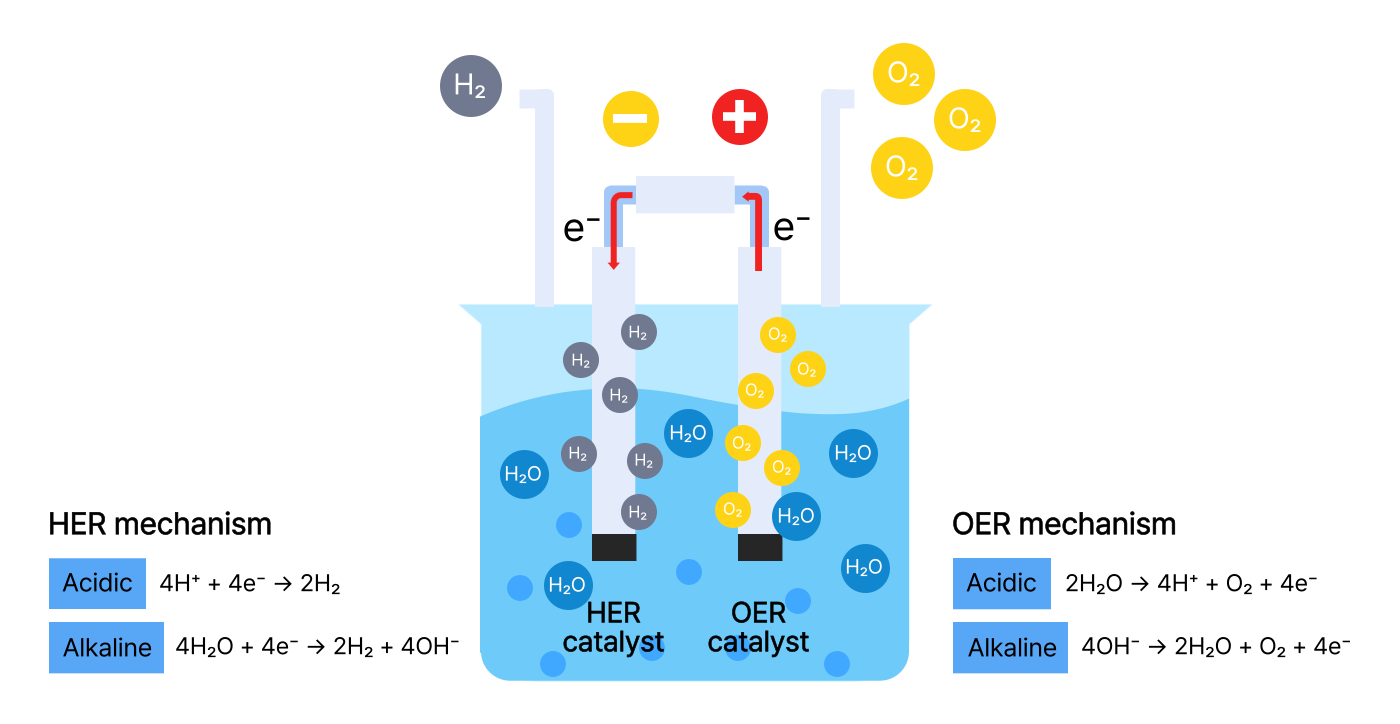

1) Hydrogen Evolution Reaction (HER) Catalyst

We are developing high-activity Pt-based catalysts to generate hydrogen with low overpotential during the water electrolysis process.

2) Oxygen Evolution Reaction (OER) Catalyst

For OER reactions, we apply IrOx-based catalysts and are also developing IrOx-MOx composite catalyst technology to maintain durability and activity while reducing Ir usage.

3. Electrode Catalyst Manufacturing and Evaluation Infrastructure

Heesung Catalysts has electrode catalyst manufacturing facilities capable of responding from laboratory level to mass production stage, and has established all facilities including catalyst analysis equipment, electrochemical evaluation equipment, and ink manufacturing and MEA (Membrane Electrode Assembly) fabrication facilities, operating a One-Stop verification system that enables full-cycle evaluation from catalyst development to actual stack application.

Technology Partner for Hydrogen Economy Response

Beyond product supply, advancing as a Total Solution Provider leading hydrogen economy expansion.

Heesung Catalysts has built a technology support system encompassing the entire hydrogen industry, from existing catalyst development·evaluation·production centers to process design, demonstration operation, and integrated solution provision. Particularly in the electrode catalyst field, we are simultaneously enhancing performance and durability based on fuel cell alloy structure design, carbon support optimization, and precious metal usage reduction technology, and are also advancing water electrolysis system response technology centered on long-term durability and economic feasibility.

Through such technology development and business structure innovation, we provide customer-customized catalyst solutions throughout the entire cycle from hydrogen production to storage and utilization. As the transition to a hydrogen society begins in earnest, we will become a technology partner that presents practical solutions to industrial sites.

‘This symposium, held under the theme “Present and Future of Heesung Catalysts Toward a Carbon-Neutral Society,” was an occasion to share Heesung Catalysts’ technological response and vision for the era’s challenges of energy transition and environmental problem-solving. Based on catalyst technologies throughout the entire hydrogen industry cycle and electrode catalyst development strategies, we once again confirmed our determination to present technological solutions at the center of change.

Going forward, Heesung Catalysts will strengthen cooperation with academia and research institutions including the Korean Institute of Chemical Engineers, and create practical changes together with customers through open innovation. Based on accumulated technological capabilities and integrated solutions, we will contribute to accelerating the realization of a carbon-neutral society.