Carbon Neutral Era: Examining the Current State of Catalyst Technology – Part 1

2025.05.07

The Korean Institute of Chemical Engineers Heesung Catalysts Symposium Review (Part 1)

Heesung Catalysts continues to drive technological innovation and strategic execution for a sustainable future under its VISION 2030: “Leading company in catalyst-based eco-friendly technologies realizing a carbon-neutral society.”

During the 2025 New Year ceremony, the advancement of environmental catalyst, hydrogen, and energy material technologies, along with the mass production of electrode catalysts and the establishment of a production system based on new facilities, were once again emphasized as this year’s key objectives.

At the Korean Institute of Chemical Engineers Fall Conference, these technologies and visions were shared externally through a special symposium themed “Present and Future Toward a Carbon-Neutral Society.” By reviewing the presentation content, we examined the connectivity with current strategies and reconfirmed future directions.

The symposium began with a keynote speech by Heesung Catalysts CEO Han Hyun-sik, followed by subsequent presentations on climate and environmental catalyst technologies for greenhouse gas reduction, catalyst technologies for hydrogen production and utilization toward a hydrogen society, development status of electrode catalyst technologies for fuel cells and water electrolysis, and trends in automotive catalyst technology development for future emission regulations.

Each presentation introduced Heesung Catalysts’ technological differentiation and development directions along with demonstration application cases, and attendees showed high interest in these solutions based on industrial reality. In this article, we will focus on “Environmental Regulation Response Catalyst Technology” and “Climate and Environmental Catalyst Technology.”

About the Korean Institute of Chemical Engineers

Founded in 1962, the Korean Institute of Chemical Engineers is Korea’s representative chemical engineering academic organization. With currently 10,889 members, it contributes to the academic and industrial development of chemical engineering through journal publication, academic conferences, and industry-academia cooperation.

The annual spring and fall conferences serve as representative academic exchange venues where researchers and industry experts share the latest research achievements and technology trends. The 2024 Fall Conference was held under the theme “Chemical Engineering Innovating the Future,” with approximately 4,000 participants and over 1,900 research presentations.

Environmental Regulation Response: Can Technological Innovation Be the Answer?

From Automotive Emissions to Greenhouse Gases: Technology Strategy for a Sustainable Future

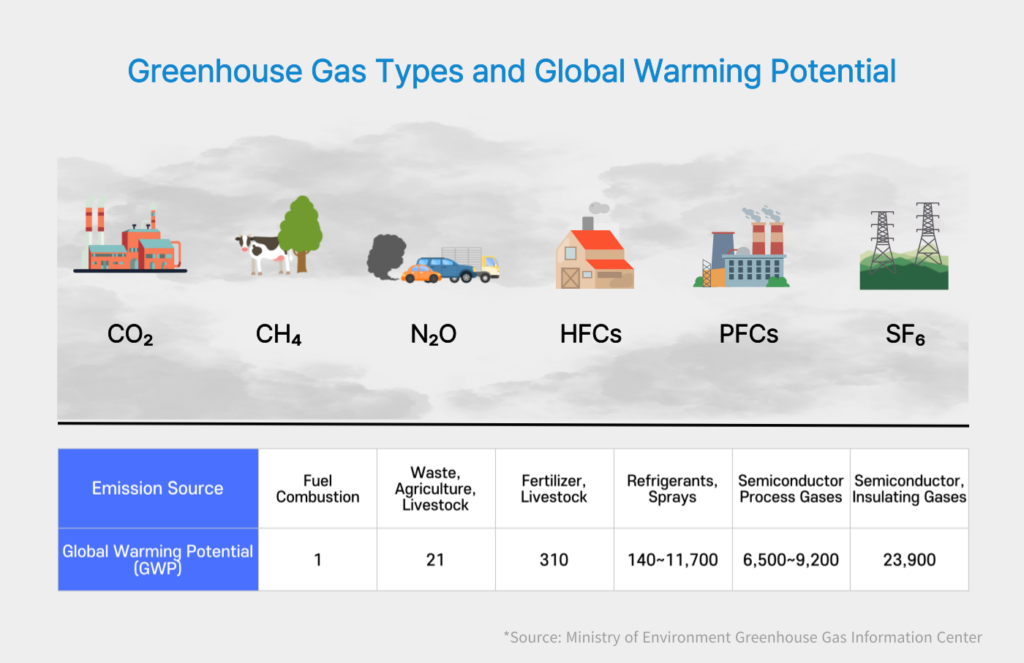

As regulations toward carbon neutrality strengthen globally, advanced environmental response technologies are required across all industries. Particularly in mobility sectors including automotive, and precision process industries such as semiconductors and displays, emission standards for air pollutants like nitrogen oxides (NOx) and volatile organic compounds (VOCs), as well as greenhouse gases including nitrous oxide (N₂O), methane (CH₄), and perfluorocarbons (PFCs), are continuously being strengthened. Accordingly, catalyst-based precision control technologies have emerged as key response measures.

Future Emission Regulation Response: Automotive Catalyst Technology Development Trends

Advanced Emission Reduction Solutions at the Boundary Between Internal Combustion Engines and Electrification

Automotive emission regulations are becoming increasingly stringent with standards such as EURO-7, US Tier-4, and Korea’s enhanced K-LEV. To respond to these requirements, Heesung Catalysts has developed advanced catalyst solutions covering both Light-Duty Gasoline (LDG) and Heavy-Duty Diesel (HDD) vehicles, presenting differentiated technologies with enhanced high activity, high durability, low-temperature response, and nitrous oxide (N₂O) suppression functions.

※ EURO-7: European Union (EU) passenger car emission regulation stage 7

※ Tier-4: US non-road diesel engine emission regulation standard

※ K-LEV: Korea Low Emission Vehicle enhanced certification standard

1. Light-Duty Gasoline (LDG) Catalyst Systems

- Three-Way Catalyst (TWC)

Low-temperature activity and high-temperature durability have been enhanced to optimize CO and NOx purification performance according to flow conditions. Catalyst stability has been improved by strengthening precious metal interactions and applying heat-resistant supports.

- Gasoline Particulate Filter (GPF)

A catalytic filter has been developed that simultaneously purifies particulate matter (PN/PM) and gaseous substances. Optimized coating technology for the carrier’s microstructure has been applied to reduce back pressure and improve regeneration performance.

- Fuel Consumption-reducing NOx Trap (FCNT)

This is a fuel efficiency improvement catalyst specialized in NOx removal and N₂O suppression functions. Purification efficiency has been increased using high-performance NOx storage materials (NSM), and this technology won the 2024 Edison Patent Award.

2. Heavy-Duty Diesel (HDD) Catalyst Systems

- Selective Catalytic Reduction (SCR)

Hybrid SCR catalysts have been developed that simultaneously improve DeNOx performance and sulfur poisoning resistance, with enhanced N₂O generation suppression functions.

- Ammonia Oxidation Catalyst (AOC)

Multifunctional AOC catalysts integrated with SCR functions have been applied to simplify systems and achieve optimal control.

- Diesel Oxidation Catalyst (DOC)

Low-temperature activity and NO₂ generation performance have been enhanced to improve purification efficiency immediately after engine startup.

- Diesel Particulate Filter (DPF)

Approximately 90% particle number (PN) filtration efficiency has been achieved, and technologies to enhance regeneration efficiency and reduce backpressure are also under development.

Climate and Environmental Catalyst Technologies for Greenhouse Gas Reduction

Climate Change Response Technology: ‘Field Application Feasibility’ Is the Answer

Climate change is no longer a distant future threat. The rapid increase in greenhouse gas emissions since industrialization has accelerated global average temperature rise, and the international community is actively responding through the Paris Agreement, International Maritime Organization (IMO) strategies, and carbon neutrality declarations by various countries.

Heesung Catalysts is developing practical greenhouse gas reduction catalyst solutions that can be immediately applied at various industrial sites. At this symposium, the following technologies were shared:

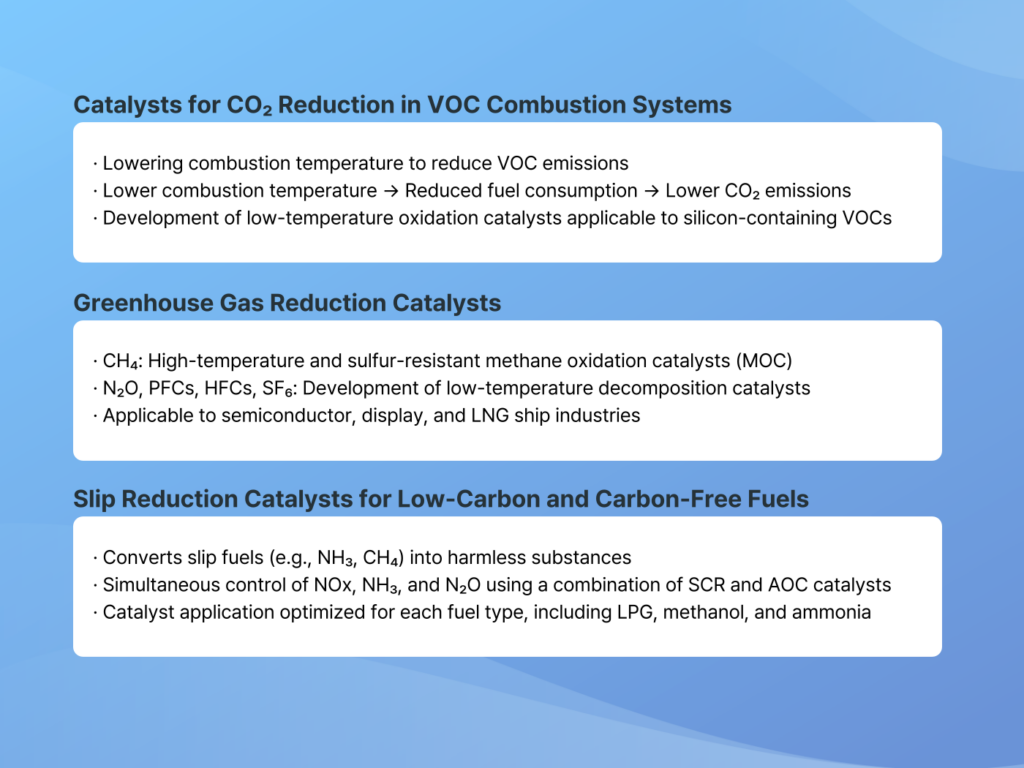

1. CO₂ Reduction Catalysts for VOCs Combustion Equipment

VOCs are generated from various industries including petrochemicals, printing, coating, and cleaning, and can cause additional CO₂ emissions during combustion treatment processes. Heesung Catalysts is developing oxidation catalysts that can purify VOCs at low temperatures, implementing technology that simultaneously reduces combustion temperature, fuel consumption, and CO₂ emissions. Particularly, poison resistance to silicon (Si)-containing VOCs has been strengthened to secure catalyst solutions applicable to various industrial sites.

2. Greenhouse Gas Reduction Catalysts (MOC, DeN₂O, DeGHG)

Heesung Catalysts is focusing on developing high-activity catalyst technologies that remove high-risk greenhouse gases (N₂O, PFCs, SF₆, NF₃, CH₄, etc.).

- Semiconductor and Display Processes

PFCs (CF₄, C₄F₈, CHF₃, etc.) and N₂O cause greenhouse effects thousands of times stronger than CO₂ when released into the atmosphere. Heesung Catalysts is developing high-durability catalyst technology that can decompose these at low temperatures.

- Transportation Sectors Including LNG Ships

CH₄ acts as a powerful greenhouse gas when emitted without combustion. Heesung Catalysts is developing low-temperature methane oxidation catalysts (MOC) with enhanced sulfur and heat resistance.

- Ammonia (NH₃) Propulsion Ships

Low-temperature NH₃ oxidation catalysts applicable to the downstream of SCR have been developed, enabling simultaneous reduction of NOx and N₂O.

3. Fuel Slip Reduction Catalyst Technology

To achieve carbon neutrality goals, the use of various low-carbon and carbon-free fuels such as hydrogen, NH₃, CH₄, LPG, and methanol (MeOH) is expanding. However, when fuel is not completely combusted or is emitted without post-treatment, it can generate secondary pollutants or greenhouse gases.

Heesung Catalysts effectively controls these fuel slip issues through specialized catalyst technologies tailored to fuel characteristics.

- NH₃, MeOH

Technology that simultaneously controls NOx, NH₃, and N₂O by integrating SCR and AOC has been developed. Ammonia conversion rates have been increased even at low temperatures, and poison resistance to sulfur components has been enhanced.

- CH₄

High heat-resistant methane oxidation catalysts applicable to various fields including LNG propulsion ships, methane co-firing engines, and landfill gas power generation are being developed.

- LPG, MeOH, and Other Fuels

Oxidation catalysts (OC) tailored to each fuel’s characteristics are applied to precisely oxidize slip substances such as carbon monoxide (CO) and hydrocarbons. These can also respond to mixed fuel systems in the initial fuel conversion stage.

Practical Solutions Based on Industrial Reality

The movement toward carbon neutrality is demanding profound changes across industrial structures and technology strategies. Strengthening environmental regulations and the pace of energy transition have presented new challenges to companies, making the necessary responses increasingly sophisticated.

Heesung Catalysts has prepared solutions with technological differentiation and field application feasibility to meet these changes, presenting specific directions and results at the symposium. This was an occasion to present practical technological solutions that can support sustainable industrial transformation, centered on automotive emission reduction and greenhouse gas response catalyst technologies.

In the upcoming Part 2, we will continue to introduce hydrogen production and utilization catalyst technologies for realizing a hydrogen society, and development trends in fuel cell and water electrolysis electrode catalysts.

➡️ 함께 보기

Carbon Neutral Era: Examining the Current State of Catalyst Technology – Part 2